For a small, independent sewing pattern company, several options exist for publishing sewing patterns for the home sewing market. Digital downloads have become dominant in the market, but as with any product left to the consumer to assemble, ensuring the accuracy of final patterns, particularly with more complex designs, is still easier with patterns printed under the control of the manufacturer. The bigger pattern producers have gone so far as to offer patterns in both printed and digital formats to appease all customers' preferences. This article will focus on options for printing patterns for sale to the home sewing market.

For a small, independent sewing pattern company, several options exist for publishing sewing patterns for the home sewing market. Digital downloads have become dominant in the market, but as with any product left to the consumer to assemble, ensuring the accuracy of final patterns, particularly with more complex designs, is still easier with patterns printed under the control of the manufacturer. The bigger pattern producers have gone so far as to offer patterns in both printed and digital formats to appease all customers' preferences. This article will focus on options for printing patterns for sale to the home sewing market.

Design Group Americas Printing Service

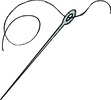

Design Group Americas (DGA) which prints patterns for the biggest brands of sewing patterns in the United States like McCall's, Simplicity, Vogue, Butterick, and Kwik Sew, offers sewing pattern printing to independent pattern makers from its facility in Neenah, Wisconsin. Other companies worldwide likely offer similar services, so investigate with pattern companies in your region if you live outside North America. While the input methods may have changed since this photo was taken around 2010, shown is an old kit with a film positive of a pattern envelope template, from left, a 49" roll of paper to use for hand-drawn patterns, a pattern instruction layout sample and stack of blank layout grids, an instructional CD, a sample pattern instruction sheet, a printing guidelines booklet, and pattern numbering samples printed in different sizes.

An advantage of contracting pattern printing through an experienced sewing pattern printer like DGA is that the printing can be done on tissue paper, something that few other printers are capable of doing. Because of the large size of sewing patterns, tissue minimizes the volume of the finished product which economizes packaging size and shipping weight. A possible disadvantage of using DGA services is that the minimum quantity required is 1,000 pieces, at least last this author checked, which could tie up small business capital and reduce the number of different patterns built up in inventory. DGA printing is done in Neenah, Wisconsin, and has traditionally been done on offset printing presses that requires printing plates created from paper copies or digital files. It is possible that printing may move to digital in the future as the company upgrades its equipment. Any of the pattern, instruction guide and envelope printing can be done in black-and-white or full color.

Some independent pattern companies have succeeding in source printing on a heavier weight of tissue than the larger companies have traditionally used, though it is possible that DGA's facilities in Wisconsin could handle this request Leisl Gibson of Oliver + S writes about finding a printer who sourced heavier pattern tissue for her, and it must be a printer accustomed to working with sewing patterns because she states the pattern folding machine would not handle her heavier paper, so all the patterns must be folded by hand. Few printers would have a folding machine set up for folding pattern tissue unless they specialized in printing patterns, so that is why it appears that she may be using a contractor such as DGA to print her patterns for her. Ms. Gibson has also stated that she uses different contractors for various parts of her printing, meaning the instruction sheets and envelopes may be printed by contractors separate from the patterns.

Printing Sewing Patterns with a Local Printer

Before deciding to print sewing patterns through DGA, it would be wise to do a cost comparison with an offset printing house locally to see if significant price savings might be possible. The vast majority of local printers will require paper heavier than tissue, and for this purpose Komar's 30 lb. plotter paper ordered in reel form is ideal. It offers a slight translucence that allows visibility for flipped patterns or fabric designs underneath the pattern paper. This heavier type of paper is easier to use than tissue for sewing because it does not rip as readily. Read our article on sewing pattern paper to learn more.

Printing Sewing Patterns on Large Format Office Printers

Printing patterns on a large format office printer offers ultimate flexibility to the home business entrepreneur. If only a handful of designs are ever intended for publication, then contracting printing through one of the methods described above is best to avoid investment in equipment. However, if multiple patterns are desired, a large format printer allows patterns to be printed on demand, reducing investment in inventory and preventing older patterns with a smaller demand from going out of stock. Komar is a full-service paper converter and can cut 30 lb. plotter paper to fit your printer's width. Komar paper is ideal for pattern printing on large format printers. Our article on sewing pattern paper provides a complete overview of paper options. While large format pattern printers are available in widths up to 72 inches (1.83 meters), staying with a 40 to 45 inch (1 meter) width printer will allow much easier loading of paper rolls. Rolls any larger must be handled by two strong people, something not always possible for the home entrepreneur. The occasional pattern piece that exceeds this width can be printed in two sections with joining marks noted.

If black-and-white printing is desired, the Ioline brand is the most reliable, economical choice recognized by most industry experts. Ioline printers work with all types of sewing pattern software, a crucial feature. The ink utilized is standard HP ink that is available everywhere. An important consideration is that this ink is not water-resistant, so excessive steam from a home iron could smear the ink. Ioline printer speed is optimized for sewing patterns and is up to four times faster than standard inkjet printers.

If color pattern printing is desired, a wide format color printer such as the HP Designjet Z3200 Photo Printer (or current upgraded model) is a good option and the one chosen for the Fashion Belle brand. This printer uses pigment inks that are water-resistant, reducing the chance of smearing if patterns are ironed flat with a home steam iron. A printer width of 44" is available, which is a couple of inches wider than most other large format printer options. A drawback to the HP Z3200 Photo Printer is that it can be tricky to get it to work with vector-based sewing pattern software (usually in DXF file format) which is unlike the bitmap-based photo files for which the printer is primarily intended. The files must be converted with software such as Adobe Illustrator that is readable by the printer, and paper lengths must be separately configured for each pattern. These challenges might be managed better with RIP software, but the cost of that is high and the software is not required. The PostScript (PS) version of the HP Z3200 is not necessary for pattern printing, and RIP software would take the place of the PS feature and be easier to update if RIP capabilities are desired. Depending on the future response to Fashion Belle patterns with different colors of lines for sizes, it is possible that our next replacement printer purchase would be a black-and-white Ioline to save on cost. However, if customers appreciate the colored lines enough to support the slightly higher cost for ink, then we may continue to use color printing.

Pictured below is an HP Designjet Z3200 Photo Printer and an Ioline StudioJet, both recommended for printing sewing patterns in a home office environment.

Printing Sewing Pattern Instruction Guides

Pattern instruction guides can be printed in many formats, including saddle-stitched booklets. The traditional large folded sheet format would be easy for a local printer to run on a press, but using a booklet format that can be copied on a standard copy machine eliminates the need for printing plates and allows for small printing runs for a home entrepreneur. A booklet format also provides greater flexibility for changes if mistakes are discovered later. If the pattern instructions are short, they can be copied on 11"x17" paper and folded in quarters with no binding required. Longer instructions might be copied on letter-sized paper that is then cut in half and bound along the short edge with side staples, though it may be difficult for a booklet in this format to lie open on a table unless flexible paper is used. A benefit of designing a format that can be copied on letter-sized paper is that the machine for copying is smaller and paper is easier to handle. The goal with an instruction guide is to ensure that it is small enough to fit into whatever pattern packaging is desired. Care should also be taken to ensure that the paper is flexible enough to lie open easily on a table with whatever binding method is used. Another option to help with a bound booklet lying open would be a saddle-stitched booklet from 11"x17" cut in half so that the short edge is bound and the weight of the longer edge will hold the booklet open.

Printing Sewing Pattern Envelopes

Pattern envelopes can only be printed by a local printer if the printer has the capability for printing on flat paper and then assembling envelopes on site. Pre-assembled envelopes do not run well through any press or copier. Rather, printing on adhesive labels which are then attached to envelopes is the preferred method if post-print envelope assembly is not possible. Another alternative to envelope packaging is a wire-bound book that features sewing instructions in the front with an envelope holding pattern pieces bound into the back of the book. This type of format may not be available through services of local printers, depending on your area, but it is easily sourced through large printing houses nationwide. Wire-bound book machines are also available for purchase for a home office, though a book style of presentation will increase manufacturing cost above that of the traditional envelope. Customers tend to be price sensitive when purchasing sewing patterns, so the justification for any added cost must be cautiously considered. Many small pattern companies use plastic ziplock bags for packaging, though this method dulls the appearance of any color photo inserted into the front of the package for display. Some pattern manufacturers take care to include a hole at the top of packaging so that patterns may be hung from display hooks.

Sewing Pattern Printing Summary

In this article, we have looked at methods for sewing pattern designers to put their work into print. DGA offers a complete package of printing that is the easiest option for someone who is starting out and has a budget for a 1,000-piece minimum printing run. For the more ambitious sewing pattern publisher, working through a local offset printing press facility could be rewarding with a cost reduction in printing, but many details will need to be handled separately, from sourcing pattern paper to determining instruction guide and packaging formats. Finally, purchasing a large format printer to bring printing into your home office offers incredible flexibility for print-on-demand patterns. However, digital pattern software and equipment will be required for that method in order to transfer patterns to the printer digitally. If someone who is familiar with sourcing printing on heavier tissue would like to share their information contacting us, that would be so appreciated! Most of all, if you have a dream of one day becoming a published patternmaker, keep the dream alive! It is possible, and the home sewing market is bursting with potential for anyone who produces innovative, well-fitting patterns.

Sewing Pattern Paper Overview

Sewing pattern paper samples photo © 2012 Fashion Belle

Next is an overview of the types of paper most commonly used for sewing patterns, from patterns made by hand, to patterns printed by large format office printers, to patterns printed by offset presses on jumbo tissue reels. Hopefully, this information which took weeks of research to compile will provide a head start for anyone seeking paper for a variety of sewing pattern applications.

Next is an overview of the types of paper most commonly used for sewing patterns, from patterns made by hand, to patterns printed by large format office printers, to patterns printed by offset presses on jumbo tissue reels. Hopefully, this information which took weeks of research to compile will provide a head start for anyone seeking paper for a variety of sewing pattern applications.

Paper for handmade sewing patterns at home

For someone who needs paper for just a few patterns drawn by hand in pencil or ink, the most economical choice is to visit a local teachers' supply store and purchase wide paper (sold by the linear foot or centimeter) that is used for covering bulletin boards or art projects. This paper, sometimes called butcher paper, has no translucence and is heavier than would be ideal for pattern use, but the economical advantage is that it may be available locally and sold in small quantities, usually to the exact length you request. If you need an entire roll of paper, visit an office or drafting supply store and ask for the least expensive plotter paper in stock, or order a roll of plotter paper online in the lightest weight available. Translucent bond in a 20 lb. weight is a good choice if you can find it by the roll.

A more expensive and luxurious option for creating durable patterns that will be used repeatedly is Swedish Tracing Paper, a lightweight, translucent fabric that can be used both for drawing patterns and for sewing together as fitting samples. Kwik Trace is similar, only with a dotted surface to aid with drawing straight lines. These products are not usually available in stores, but an internet search will list dozens of retailers from which they may be ordered.

Paper for handmade sewing patterns in commercial design rooms

In apparel production environments, especially in older shops where patterns are still made exclusively by hand rather than with the aid of a computer, two types of paper, hard and soft, are used for patterns. Marker paper, commonly called soft paper, is printed with a grid of letters and numbers to aid in laying out pattern pieces and in drawing straight lines and angles. The alpha-numeric design of marker paper is most useful for alignment when drawing markers, which are layouts of pattern pieces in all sizes to be cut. When marker paper is used to create first patterns, it is sometimes flipped so that the less distracting blank side is up, especially for styles with more curves than straight lines. Once a soft paper pattern has been perfected, it is stapled to a manilla-colored tagboard that sometimes has a green backing (also known as hard paper or pattern paper) and then cut out to maintain a durable copy. Hard paper patterns are easy to trace and are therefore favored when making markers or when tracing an old pattern back onto soft paper in preparation for designing a new style. For storing, a large hole is punched in each hard paper pattern piece and all the pieces for a style are fastened onto a pattern hook that has a string and bar at the end. The pattern hooks with the patterns are then hung on a clothes rod. This system of patternmaking was standard through most of the 1900s, but now computerized patternmaking has almost completely replaced it. Only a few high-end, custom shops still work exclusively with paper patterns. Marker paper, pattern paper tagboard and blank plotter paper (mentioned below) may be purchased in bulk from Komar in North America or worldwide from other wholesalers that serve apparel cutting and design rooms.

Paper for a combination of computerized and handmade sewing patterns

Many manufacturers rely on a combination of paper and computerized patternmaking, in which case neither marker paper nor pattern tagboard is used. First patterns are created with the same white paper used in the pattern plotter, usually a heavyweight bond that may be printed with an old pattern as a starting point for the new design. When the first paper pattern is complete, it is then digitized into a computer and reprinted as needed. Other manufacturers drape patterns in muslin and digitize patterns into a computer from the muslin pieces. A few of the largest clothing manufacturers reduce development costs by insisting that patterns be created exclusively through computerized methods, and in those cases, even computerized markers can be transferred digitally to automated cutting machines so that paper copies of patterns are rarely printed. When clothing is the end product, rather than the printing of patterns themselves for sale, the quality of paper on which patterns and markers are printed is not as important, and a recycled newspaper product like Komar's Enviroplot is one of the least expensive options. Heavy, white plotter paper is still the most popular choice for design room plotters, however, largely because of its stiffness that makes it easier to handle compared to recycled newspaper.

Paper for printing sewing patterns for the home sewing market

Though the Fashion Belle website has started out as a modest clothing and sewing pattern resource directory, the primary purpose of the site is to host a new sewing pattern collection for women. Years of work and research have laid my personal foundation for becoming a sewing pattern manufacturer, including sewing experience, a university degree in apparel design and work as a patternmaker for six companies around the United States. Publishing patterns requires more than just knowledge of patternmaking, however, especially when equipment and supplies are chosen. I am grateful to many industry experts who have pointed me in the right direction, including several who helped educate me about printers and paper. The following is a summary of my findings regarding printing processes and paper that is most suited to small office pattern publishing for the home sewing market.

Sewing pattern printing methods

When I started to research the type of paper that would be best for printing sewing patterns, several decisions were already in place. I knew it would be impossible to trace patterns by hand and sell them with any volume or profit. McCall Pattern Company offers printing services to individual designers but requires minimum printings of 1,000 patterns at a time. I felt that with the number of different designs I intended to produce, I could achieve greater control over investment in stock if I owned equipment to enable me to print patterns one at a time, as they were ordered. This meant purchasing OptiTex pattern software, a used digitizer found on Craig's List and a large format printer to print patterns from my home office. The printer I selected was a 44" (1118 mm) wide HP Designjet Z3200 Photo Printer with water-resistant color inks. Different colors allow size lines to be more visible for cutting, and water-resistant inks resist smearing when steam irons are used to flatten the patterns.

Sewing pattern paper weight

Most established sewing pattern companies print on tissue, and I originally began looking for translucent paper to use in my printer to imitate that process. From experience, I know that when placing patterns on printed fabric for cutting or when flipping a pattern piece to the opposite side for cutting, it is important to be able to see through the pattern paper. This is balanced with the difficulty of handling tissue that is too thin. McCall, Simplicity and other pattern companies that print on tissue use offset printing presses that keep jumbo tissue paper reels under tension while printing. Even with offset printing, I have occasionally encountered commercial tissue patterns with large rips, so the process is not foolproof. So, I looked for tracing paper that had the beneficial translucence of commercial patterns yet a heavier weight that was rip-resistant and easier to handle. The problem with tracing paper for my application became apparent when I tested high-quality stock from a Wisconsin paper converter and found that even though it was thicker and stronger than the tissue paper used by major pattern companies, it was still too thin to withstand the printing motion of my HP Designjet. As a side note, two types of tissue on rolls similar to that used by commercial pattern printers are separating tissue and dye sublimation paper, available through Beaver Paper and other suppliers. Both are too lightweight to withstand the motion of a large format office printer.

When I realized that the lighter tracing paper weights would not work with my printer, I transitioned to the next level of weight with vellum and heavy tracing paper designed for use with plotters and photo printers. Vellum handles easily and offers excellent translucence, but it retains crease marks when folded and pin marks when punched, making it undesirable for use with sewing patterns. Both vellum and plotter tracing paper are very expensive, and I knew my market would not support that level of cost. A cheap alternative to vellum, often used by architects for printed drafts, is translucent bond. The lightest weight of translucent bond available, around 20 lb., is not that translucent, despite its name. When used for sewing patterns, translucent bond is thick enough to obscure fabric patterns when laid on top and to disguise pattern markings when flipped to the opposite side. Because the type of economical, strong, translucent paper I needed appeared to be rare, I began inquiring with international paper mills about shipping jumbo reels of specialty paper and with trucking companies and paper converters about processing and delivery. I learned that the greatest economy is to be found in ordering a minimum of one 20 foot container (around 18 metric tons) for overseas shipment that fills an entire truckload once landed at a port of entry. This volume is common for large, established publishers but not for companies just starting out like mine. Paper manufacturer Arjo Wiggins deserves thanks here for responding to my inquiries about shipping quantities smaller than a full container.

By chance one day, when I had almost decided it would be necessary to settle for non-translucent pattern paper, I saw a temporary posting by another pattern company referencing their paper supplier as Komar Alliance, a North American supplier to the sewn products and industrial packaging industries. I contacted Phil Glauben, the representative for my area, and found him to be extraordinarily helpful in answering my questions and sending samples for testing. Komar offers three weights of plotter paper, and the 30 lb. (or 30#) offered the perfect combination of translucence, strength and cost for my use. Komar calls its 30 lb. plotter paper a "bond," however my best guess is that it actually rated by the "offset, book, text" standard of basis weight, since the weight of Komar's 30 lb. is much lighter than the 20 lb. bond that is popular for use in copiers and desktop printers. The various rating systems for paper "weight," or thickness, can be complicated to compare when shopping for wholesale paper. The standard European way of expressing paper weight is in grams per meter squared (g/m2 or gsm). In the United States, a system called "basis weight" is more common, but with proper calculation, measurements can be converted from one system to another to facilitate price comparisons. Wikipedia offers an explanation of paper density ratings and a chart showing how 30 lb. offset is a lighter weight, and therefore more translucent, than 20 lb. bond.

Sewing pattern paper width

Komar maintained stock of the weight of paper I needed, but the width I needed was not standard. I preferred 44" wide rolls to utilize all of my potential printing area. Printer and paper widths of 42" (1066 mm) are much more common, so I realized that I might need to settle for 42" paper rolls, since custom cut rolls are usually expensive. However, I wanted to exhaust all my possibilities for a 44" width before giving up. Those extra two inches would affect the styles that I could produce, since once grading is completed, not all sizes print comfortably on 42" wide paper. Eventually, Mr. Glauben put me in touch with staff at Komar's full-service paper converting facility in California, and I learned that they could cut 48" stock rolls down to my desired width of 44". They could also roll the paper to my specified diameter to fit on my printer's paper spindle so that I would not need to use a free-standing spindle to handle large diameter rolls. Another benefit of smaller rolls is that I could lift them myself (something I knew would never happen with the 72" wide printers that are more common than the 44" widths for pattern printing, back to my original decision on printer width). When Komar sent the final quote for a pallet quantity of paper, I realized the pricing was superior to anything else I had found, even though I was paying for the excess that was discarded from the 48" original rolls. I also ordered two rolls of muslin for draping patterns at an excellent price.

When I received the paper, I saw the label "Ioline bond" and investigated to find that Ioline, the emerging leader in plotter manufacturing for the apparel industry, also sources paper from Komar as do many other Ioline plotter users. This connection alone is a high recommendation for the value of Komar's paper, and the breadth of this user base led to labeling of the packaging specifically for Ioline.

Garment industry suppliers

Readers who live in regions outside of North America will surely be able to find suppliers similar to Komar that stock pattern paper suited to various patternmaking applications. Search the internet for suppliers to the sewn products industry in your country, and visit trade shows if possible. While Komar is, of course, one of many garment industry suppliers in North America, it is one that is open to working with all sizes of businesses, and this is an important consideration for companies starting small and seeking to build a relationship with suppliers. In the long run, finding a reliable supplier at a reasonable cost is better than switching orders around to multiple companies in constant search of slightly better pricing.

For me, Komar turned out to be my dream supplier. I was thrilled to obtained the perfect combination of roll width, diameter and cost, since weeks of prior research had led me to think this would be almost impossible. Sales manager Phil Glauben serves large accounts that order truckloads of products delivered to warehouses every week, yet he was just as happy to meet with me personally, send free samples and then ship a pallet order to my home office. The paper and muslin I received have been perfect for my needs, and the prices were better than anything else I had found. I look forward to being a long-term, growing customer. This concludes the story of my quest for the perfect pattern paper, and I hope this information will assist others who are looking for paper for similar applications.

Sewing Pattern Paper and Printing Discussion

The content above generated discussion among several industry patternmakers. To preserve those comments with valuable information, they are reprinted here.

Cost of Printing Pattern, D.B., 10/6/2012

What do you feel your cost is to produce a sheet of pattern drawings, and how fast is the plotter producing them? We are a pattern design company and currently use McCall's, however the 1000 piece minimum gets very costly. Your research was very interesting and we would like to see if this would work well for our company. Thanks.

Plotter printing always more expensive than offset press, Fashion Belle, 10/6/2012

D.B., thanks for your response to the article. Many variables enter into the cost of plotter printing (full color inks vs. black, the number of sizes per sheet, the amount of additional text, the total number of patterns needed), and I am happy to offer advice based on a specific situation. You may reach me via the contact form. While I do have a general idea of cost, I have not done enough pattern printing yet to have hard numbers on my cost per linear foot, though I will be charting this closely as my business moves forward. This article provides a cost per square foot of $1.76 for full color photo printing including ink, print heads and paper for the same printer I have, an HP DesignJet Z3200. Of course, printing for patterns, that leaves most of the page blank, utilizes far less ink. I recently placed an order through Atlex for double packs of replacement cartridges for my printer (these are water-resistant inks), and the cost was just under $1,000. The gloss enhancer and photo black are not used on bond paper, so my order excluded those. Atlex's ink pricing is excellent, and they also sell photo printers, though I ordered my printer through a local dealer before I learned about Atlex.

The Ioline plotters utilize black ink that is less expensive but not water resistant, so if your customer irons patterns with any steam by accident, the ink may smear or stain fabric. Ioline plotters are easier to set up to sync with pattern software systems like industry leader OptiTex, so if you want to print directly from pattern software without going through a secondary program like Adobe Illustrator, then an Ioline plotter is the best choice. I chose full color printing because I like the size lines to be easily differentiated, and I am working to choose colors that are lightly saturated to conserve ink. As for speed, the technical specifications of each plotter or printer lists printing speed. Any large format printer can run on a queue that prints around the clock, so if you are distributing only a few hundred patterns per day, the speed should be adequate. If you are selling patterns by the thousands, offset press printing such as offered through McCall will always be less expensive per pattern than plotter printing. The more patterns printed, the better the cost advantage of going with offset printing.

You might considering ordering Komar paper (described above) by the reel and engaging a local offset press to print your patterns to get the cost below what McCall offers. I prefer the flexibility of changing pattern files and printing patterns on an as-needed basis, which is why I chose to bring printing in house.

Another option you might consider is grouping patterns into a collection and printing a wire-bound instruction book with an envelope in the back holding patterns for several styles. Examples of this are common in fabric stores, and this would allow you to raise your minimum order for a single printing project while still making a variety of patterns available. You could self-publish books or find a publisher who might be interested in your collections who has existing marketing avenues in place. I am interested to hear what you decide to do.

Pattern Printing, D.B., 10/19/2012

Thank you for your response back. My wife has . . . had them produced by McCall's for many years. We are looking at what is cost effective in not having money tied up in inventory (1000 pieces each pattern) or paying a little more and printing as we need them.

I checked out Komar's paper and even got a couple of samples to try. We have looked at HP Plotters T-1300, as we would only be printing black and white. We have also looked at a couple of LED plotters that would reduce the cost of toner/ink. We then had to think about folding and packaging. Your information that you did on the forum was great, gave us lots of ideas, however when you look at the cost of the equipment, it makes you wonder if it is worth it. I like the idea of having it in house.

I am interested in how your printing progresses and what your actual cost and time it takes to print a pattern will be. Thank you for all of your ideas and hope to hear how your printing works for you.

Pattern Packaging, Fashion Belle, 10/20/2012

. . . Yes, I will report back on my actual costs once production printing begins. I would recommend an Ioline plotter if you want black ink only. Ioline plotters are designed to work with all types of pattern software, a crucial feature, and they utilize standard HP ink cartridges available everywhere. They are also several times faster than most inkjet printers.

A separate article could be written on packaging, which relates directly to how patterns will be folded. I've experimented with boxes and tubes, but I'm coming back around to envelopes as a preferred option, both to reduce shipping costs and storage space. When printing in-house, I cannot imagine any way to fold patterns except by hand. Patterns of great length may need to be plotted in several sections and cut apart to make folding easier. Most plotters have auto cutters.

The real expense with in-house packaging is the front cover illustration, especially if it is done in color. My plan is to outsource the front cover illustration, possibly to a color copy shop or an offset printer. Multiple cover illustrations can be placed on one offset printing plate, increasing the economy of each printing run. Some in-house pattern companies use clear plastic bags for packaging so that the cover illustration can be printed on square cardstock and inserted. Others outsource the printing and assembly of the entire envelope, which is what you have been doing with McCall, but most offset printing shops also have this capacity.

You are facing a delicate decision. Offset printing will no doubt be less expensive for large volumes, but printing in-house allows a broader inventory for specialty sales. My own hope with in-house printing is to have an inventory of hundreds of patterns that are printed on demand, and I am also looking toward formatting patterns for digital download, which will especially be an advantage for capturing international sales since shipping and customs clearance is so complex as to prevent most hard copy sales offshore.

Have you started printing patterns yet? D.B., 12/27/2012

I was just checking back to see if you had started printing yet. We just purchased a used HP Plotter a Z-2100, to test and see if it will work for us. We have done several test runs and I do feel that it will work for us. I found a mechanical folding machine that will help in folding the patterns. JoAnn is very excited that she can now change some of her pattern designs easily and not have to order another 1000 from McCall's. She is also going to add some color into the patterns. We think that overall our customers and dealers will like the new print. They get more durable paper and a reclosable bag that they can actually put the pattern back into.

I again wanted to thank you for all of the research that you did, made it very easy for us to look at another way of producing the patterns.

Thanks for the update! Fashion Belle, 12/28/2012

Thanks for the update! I am excited to see more of what you will be doing . . . I totally agree with "a bag that you can actually put the pattern back into." The slim paper envelopes from the big companies are rarely big enough once the pattern has been used. I am experimenting with several options myself, including muslin drawstring bags with printed canvas labels sewn on, showing the pattern designs.

Update to our Printing, D.B., 4/06/2013

I thought I would update you on what we are doing with our printing. Since the last time I wrote you, we have purchased another T-series Plotter. We have found that they print much faster than the Z series. We have two T-610/44 plotters. We purchased them used and have found them to be very durable. We are completely changing over to printing our own patterns. Thanks to your initial article, we really have found that printing our own patterns is much more cost effective for us.

We have worked with Komar to get them to make the 44 inch 30# paper rolls. I do believe that our customers like having the colored lines to cut out the pattern. We did have some push back on the size of the patterns and the shipping cost, however the quality of the bond paper over the tissue has really won them over. We also have so much control over how the patterns are made and we ease of being able to change if needed. We can also get more patterns printed with out such a huge outlay of capital. We have released two new patterns, reissued two existing patterns and will be releasing two more in the next couple of months.

I am now looking into purchasing a folder, they are expensive but over time will very much pay for themselves. In the future we will look at getting a more production plotter that has the large ink wells, like an HP 4500 or the new T-7200. This will lower our ink costs drastically.

Congratulations on in-house pattern printing! Fashion Belle, 4/7/2013

Thank you for the update! That is interesting that your customers are willing to endure a larger pattern package size and increased shipping costs in order to have more durable paper. These were concerns I had evaluated but had not yet experienced in production. I work for another company in the spring of each year and hope to begin my own pattern publishing before the end of 2013. It is good to hear your comments on colored lines. I have felt that they are superior, but it adds cost, and it is hard to know at what price customers will resist purchasing patterns regardless of quality.

Cartridges in my HP Z3200 may be refilled, but it is complicated because of the water-resistant pigment inks used by that model, so I am just purchasing cartridges currently. More is written about my printer on this page, Sewing Pattern Printing for the Home Sewing Market. I am curious to know more about your folder when you find one, as I have not researched that yet. Thanks for keeping us updated on your progress. Congratulations on your success at bringing pattern printing in house!

Useful, K., 3/12/2013

Every now and again, I do a web search for large format pattern printers and today, this entry popped up. I've been a pattern maker in the garment industry for 30+ years and have been thinking about producing a retail pattern line. . . . A word about the Ioline plotters. There are two kinds. One is a pen plotter and the other is an inkjet. It is the inkjet that may pose a problem with smears and what not. I have an Ioline 600A which is the pen plotter. This model is also larger than any of the 44" HP printers, mine is rated for 72" output. I also use Komar for some supplies, definitely paper (marker, plotter and cutting tissue). I wasn't as pleased with my last muslin order but so it goes.

But I digress. A lower cost option can be a pen plotter rather than an inkjet. I occasionally have inkjet envy (I have a pen plotter) but inkjets aren't the best choice in my very arid climate. The consumables (ink) are basically free with this particular pen plotter (Ioline 600 A) because it will take just about any pen (the owner designed it that way). The downside is that you can only use one color ink and only one line thickness. For manufacturers, this is no problem since we need the thinnest possible line. Another benefit of pen plotters is that they are faster than inkjets. I think the top speed on mine is 30 feet a minute but that varies depending on number of pieces etc.

My plotter is a bit noisy but it isn't dramatically so. You can still talk on the phone while it is running. I plan to re-arrange my shop to put the plotter in the bay with all the industrial machines if I end up using it to plot retail patterns because it going all day would annoy me.

If you need to output Illustrator generated files, make certain that the software and particular plotter you have in mind are compatible. I haven't investigated whether my plotter will print Illustrator modified files but I suspect that if it did, it wouldn't be with whistles and bells so formatting the illustrator files to be complimentary with pen output would have to be very simple -single lines and no fancy fonts.

The Ioline plotter I have is about double the cost of the HP 44" ink jets. New, mine was $11,000. Then again, maximum output is almost twice that -72". This could be a good value if you have large pattern pieces. Not so good if your pieces are small, such as baby or children's clothes or craft items.

If you live in a garment area, you could probably pay less for a used one. This unit is a work horse and it is easy to maintain and repair. In fact, I selected this plotter after calling 3 different plotter repair places and asked which model/brand they repaired the least. They all said this same brand and model. All seemed rather enthusiastic about it, that it was so simple that most people could repair it themselves. By the way, no affiliation, just a satisfied customer. Also not saying other brands/models aren't as good, I don't know. Anywhere I ever worked, we had in plant mechanics to fix stuff so I never had to worry or think about it.

Thanks K.! Fashion Belle, 4/7/2013

Thank you for visiting my website and leaving such an in-depth comment! Your comment about the Ioline inkjet printers smearing is helpful. My concerns about smearing, especially around steam irons that home sewers use to flatten pattern creases, led me toward an HP photo printer instead of an Ioline, even with increased ink costs. Pen plotting is ideal for production, but with retail patterns, I do plan to include markings that could be difficult for pen plotters, plus the nested patterns for home sewers are easier to use with colored lines. Thanks for the information!